As a packaging product, boutique cans are attracting more and more attention from merchants. To make a fine tin box beautiful, in addition to the shape of the box, the most important thing is the design and printing of the pattern. So, how are these beautiful patterns printed on the tin box?

The principle of printing is to use the physical properties of water and ink exclusion. With the help of the pressure of the roller, the graphics on the printing plate are transferred to the tinplate through the blanket. It is an “offset printing” technique.

Metal printing can be divided into four-color printing and spot color printing. Four-color printing, also known as CMYK printing, uses yellow, magenta, cyan primary color inks and black inks to reproduce color originals, so it can produce color printing effects. Most of the various colors of four-color printing are composed of a certain proportion of dots. Dot density and controlling are key factors in color. Compared with spot color printing, the probability of ink unevenness in four-color printing is slightly higher.

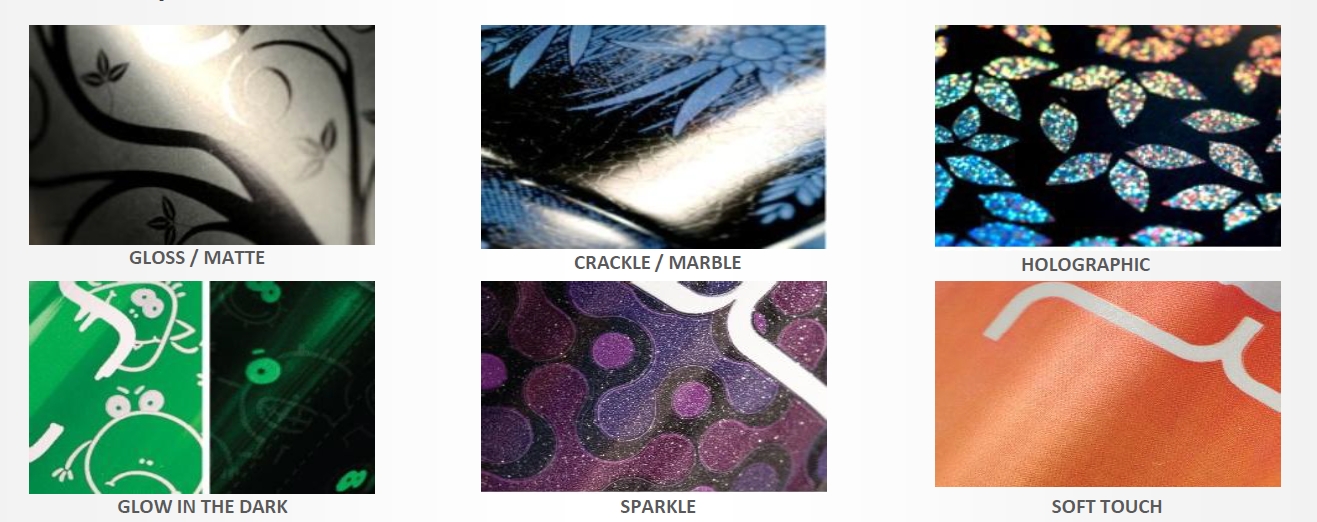

After the tinplate can pattern is printed, a layer of protective oil needs to be attached. At present, there are gloss varnish, matt oil, rubber oil, orange oil, pearl oil, crackle oil, glossy printing matt and other types. For example, the bright luster of the gloss varnish makes the pattern more dazzling and brighter, while the matt oil is more pure and the pattern is fresh and elegant.

Will the ink used in tin box printing produce pollution? This is a question many people have. There is no need to worry about the safety of coating inks. The coating inks used in tinplate cans are all in line with food-grade and environmental protection standards, and can be directly used in food packaging. The ink generally used for pattern printing of tinplate cans is called metal ink, which has good stretch adaptability and is widely used in metal product printing.

Post time: Jul-22-2023