The surface decoration of tin cans has undergone a major transformation, transforming these everyday items into fascinating works of art. Various techniques are used to enhance the beauty of tin cans, making them suitable for a variety of uses, from packaging to decorative crafts.

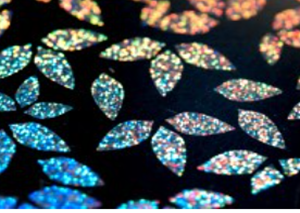

One of the most striking surface decoration effects is the holographic t reatment. This technology uses a special film to reflect light, creating a three-dimensional appearance. The holographic effect is achieved through a process called hot stamping, which uses heat and pressure to apply a metallic foil to the surface of the tin can. The result is a vivid, eye-catching design whose color changes depending on the angle of the light. To achieve this effect, manufacturers need specialized machinery, such as a hot stamping machine, and high-quality holographic foil. The holographic surface decoration effect not only enhances the visual appeal of the tin can, but also adds a layer of sophistication, making it ideal for high-end products.

reatment. This technology uses a special film to reflect light, creating a three-dimensional appearance. The holographic effect is achieved through a process called hot stamping, which uses heat and pressure to apply a metallic foil to the surface of the tin can. The result is a vivid, eye-catching design whose color changes depending on the angle of the light. To achieve this effect, manufacturers need specialized machinery, such as a hot stamping machine, and high-quality holographic foil. The holographic surface decoration effect not only enhances the visual appeal of the tin can, but also adds a layer of sophistication, making it ideal for high-end products.

Another popular surface decoration technique is the crackle effect, which mimics the look of an aged or weathered surface. This effect is achieved by applying a crackle medium over a primer. As the medium dries, it shrinks and forms a network of fine cracks, revealing the underlying color. For tin cans, this technique can be achieved using a spray paint or brush-applied crackle medium, which are readily available at craft stores. This process requires little to no machinery, as it can often be done by hand. The crackle surface decoration effect adds a rustic charm to tin cans, making them perfect for vintage-themed projects or home decor.

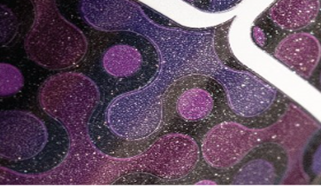

Glitter is another fascinating surface decoration technique that can enhance the look of a can. This effect is usually achieved by incorporating glitter or metallic particles into a clear coat or paint. When glitter is applied to the surface of the can, it creates a dazzling effect that catches the light perfectly. To achieve this, manufacturers often use an airbrush or spray gun to ensure an even application of the glitter coating. Glitter surface decoration is particularly popular during the holiday season as it can add a touch of glamour and excitement to any project.

The glow-in-the-dark effect is a unique surface decoration technique that adds an element of surprise to tin cans. This effect is achieved using phosphorescent materials, which absorb light and then emit a soft glow in the dark. To achieve this effect, manufacturers typically use glow-in-the-dark paints or powders, which can be applied using a brush or spraying technique. The machinery required for this process is similar to that used for traditional painting, so it can be used for both mass production and DIY projects. The glow-in-the-dark surface decoration effect is particularly attractive for children’s products or themed events as it creates an enchanting atmosphere.

In summary, the surface decoration effects of tin cans cover a variety of techniques, including holographic, crackle, glitter and luminous effects. Each method has a unique visual appeal and can be achieved using specific materials and machines. As the demand for exquisite packaging and decoration continues to grow, innovative surface decoration technologies for tin cans will undoubtedly play an important role in enhancing their functionality and charm. Whether for commercial use or personal projects, these decorative effects provide endless possibilities for creativity and expression.

Post time: Dec-13-2024