Product Center

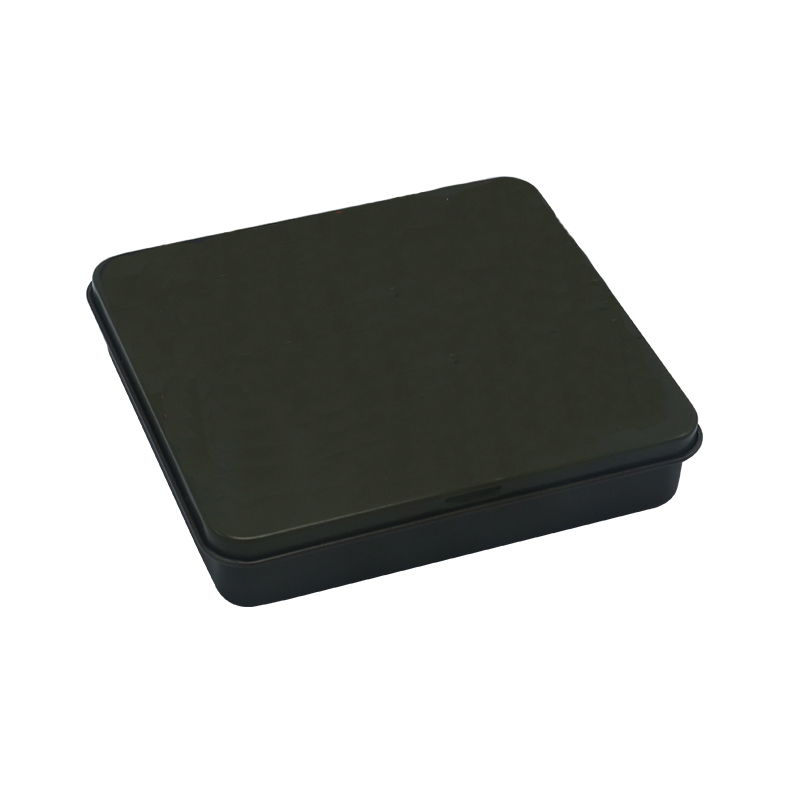

Rectangular Hinged Tin Box for Cigarette

Product Description

This hinged tin packaging can accommodate 20 pieces cigarettes. Its structure of roll-out edge for both lid and body makes buyers easier to open. One or two craved-in function point on front lid edge can well control the opening and closing of this box. Matt vanish printing all over outside on this tin box allows the box to keep the nice touching. Besides matt finish, we have glossing varnish, glossing & matt finish, wrinkle varnish, crackle finish, rubber finish, pearl ink finish, orange peel finish, etc. Any finish you prefer, we can make it for you.

Several kinds of tinplate are also offered to achieve different effects including normal one, shiny tinplate, sand blasted tinplate, mesh tinplate and galvanized iron.

As for the printing, we use offset printing to achieve low cost, high efficiency, high accuracy and great effect of color with less possibility of fading. Both CMYK and pantone are available. It can be CMYK printing. It can be pantone color printing. It can also be combination of both CMYK and pantone color printing. We have employed master experts working for over 50 years in printing industry. They can exactly figure out and mix the right colors for you.

In addition, we introduce laser coding machines including carbon dioxide coding machine and fiber optic coding machine, which allows us perfectly apply your QR code and bar code to surface of tin box. The two machines could better avoid waste and extra cost through coding.

We can also do customization for you if you would like to pay for the mold cost. As long as you can dream it, we can make it.

Mold building lead time: generally 30 calendar days.

Sample lead time: Generally it takes 10-12 calendar days to make samples of tin packaging.

MOQ: We are flexible on MOQ to meet different customers’ requirements. Customer satisfaction is our highest priority.

Delivery time: Goods will be ready for shipment in warehouse in 35-50 calendar days right after artwork and samples are well confirmed, depending on the order quantity and production schedule.

If you are looking for ways to make some specific words or images on the tin box to look prominent, our embossing skills also can help to achieve the effect. We have three types of embossing skills which are flat embossing, 3D embossing and micro embossing, all of these can be designed as requested.

Both CMYK and pantone are available. It can be CMYK printing. It can be pantone color printing. It can also be combination of both CMYK and pantone color printing. We have employed master experts working for over 50 years in printing industry. They can exactly figure out and mix the right colors for you.

Above the printing, there is a protection layer which we call varnish or finish. We have glossing varnish, matt varnish, glossing & matt finish, wrinkle varnish, crackle finish, rubber finish, pearl ink finish, orange peel finish, etc. Any finish you prefer, we can make it for you.

All of our products can be assembled by different pad or filler which are in different kinds of materials such as sponge, plastic, paper and so on.